Power Conversion.

SEPTEMBER 2025.

Power Conversion Device Manufacturers: 800V Architectures Driving Market Transformation.

As artificial intelligence continues its meteoric rise, datacenters are experiencing an unprecedented surge in power demand. The explosion of AI workloads has pushed rack densities upward and driven power requirements from traditional levels—such as 100kW per rack—to projections surpassing 1MW in the near future. This dramatic load growth far exceeds what legacy 48V or 54V in-rack power architectures can support, placing significant strain on both physical infrastructure and energy efficiency. To address these challenges, the industry is rapidly shifting toward an 800V high-voltage direct current (HVDC) architecture.

Mercator believe power conversion device manufacturing to be an interesting sector driven by fundamental shifts in two major market segments: data centers deploying 800-volt bus architectures and the automotive industry's transition to higher voltage electric vehicle systems. These parallel developments are creating a demand for advanced power conversion technologies with few historical precedents, positioning specialized manufacturers for substantial growth.

To detail some of the physics driving this shift to higher voltages, power (P) is equal to voltage (V) times current (I): P=V×I⁽¹⁾. For the same power output, increasing the voltage allows the current to decrease proportionally. For example, while at 48V it would require over 166amps, delivering 8 kW at 800V would only require 10 amps. Lower current significantly reduces resistive losses in wiring and components.

Current induces heat in wires and electronic components. This is governed by a relationship known as "I squared R loss" or Joule heating, which shows that power losses increases with the square of the current and directly with the wire's resistance (P=I2R). Lower current at higher voltages means significantly less heat is generated, increasing overall system efficiency and reducing the need for thermal management. In data centers, thermal management (cooling) can account for 40-50% of the non-IT energy overhead⁽¹⁾, and cooling systems contribute 15-25% of data center capital spending, only surpassed by IT and power distribution infrastructure.

Modern AI GPU racks can now require upwards of 140kW demanding currents of 350mps, which in turn, assuming 54V power supply, sees copper cable deployed of 500MCM (millimeter circular mil)⁽²⁾. To supply a 1MW rack at 54V, the required current would be 18,500amps and in order to carry this safely (using the same design current density of 4.5amps per mm²), would require 4,115mm² of copper cross-section, equivalent to approximately 8,121 MCM (thousand circular mils)⁽³⁾. This equates to a cable of 7.2cm in width, similar in diameter to standard tennis ball, illustrating just how impractically large such a cable would be for power delivery at low voltage.

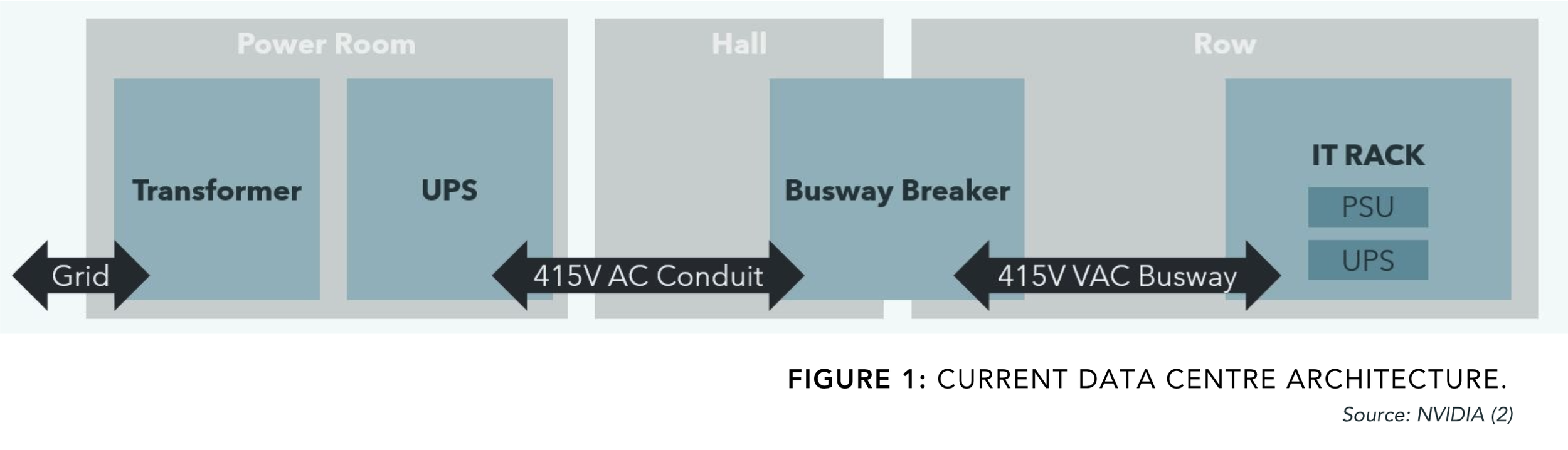

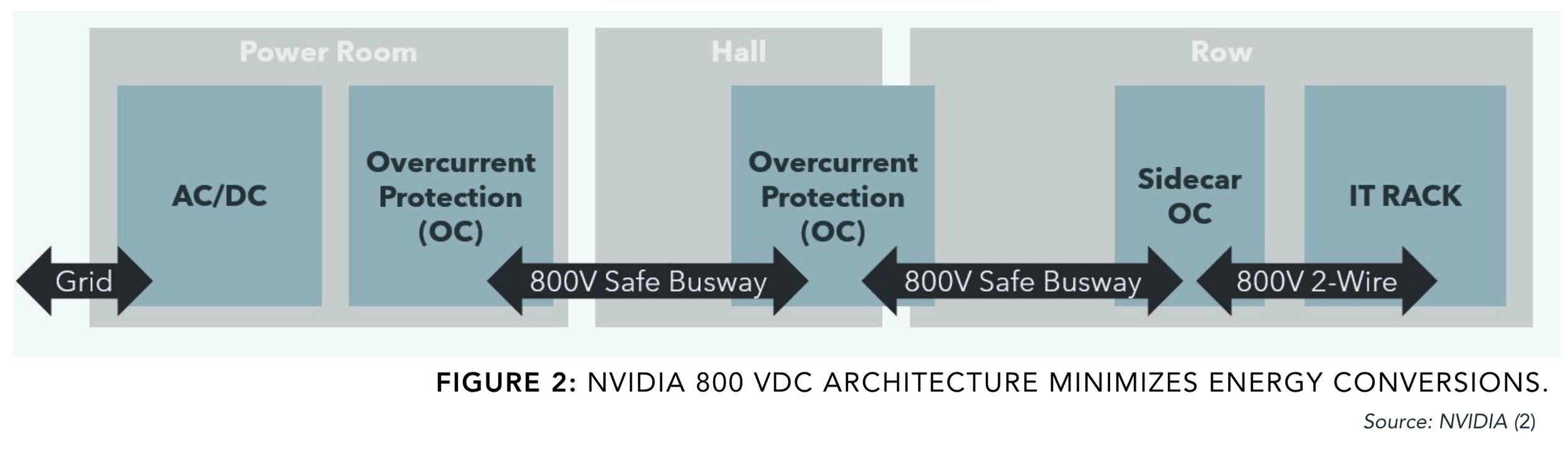

The data center industry is hence undergoing a radical transformation as artificial intelligence workloads drive power requirements from today's 100kW per rack to over 1MW in next-generation AI facilities. NVIDIA is at the forefront of this transformation, working with a cohort of industry partners to develop 800V HVDC systems that address critical infrastructure bottlenecks. 800V systems reduce current requirements by 85% while enabling 45% reduction in copper usage compared to traditional AC systems.

The efficiency gains are substantial. 800V architectures can improve end-to-end efficiency by up to 5% compared to current 54V systems while supporting scalable power delivery from 100kW to over 1MW using the same infrastructure. This scalability is crucial as data center operators prepare for the projected 165% increase in global power demand by 2030.

The automotive sector's shift to 800V architectures parallels data center developments while addressing different performance imperatives. Electric vehicle manufacturers are adopting 800V systems to enable ultra-fast charging capabilities, with vehicles like the Porsche Taycan and Hyundai IONIQ 5 demonstrating charging speeds that can add nearly 100 miles of range in 10 minutes.⁽⁴⁾

The technical advantages for the automotive industry are also significant. 800V systems enable the same power delivery with half the current of 400V systems, dramatically reducing resistive losses and enabling, similar to data centers, thinner, lighter cables. This translates to improved vehicle efficiency, extended range, and reduced material costs.

The transition to 800V architectures in both data centers and automotive applications is fundamentally enabled by wide bandgap (WBG) semiconductor technologies, particularly silicon carbide (SiC) and gallium nitride (GaN). These materials offer superior performance characteristics that make high-voltage, high-efficiency power conversion economically viable. SiC devices provide critical advantages for 800V applications, including higher breakdown voltages, superior thermal conductivity, and reduced switching losses compared to traditional silicon. GaN technology complements SiC in lower-voltage, high-frequency applications within 800V systems. GaN devices enable switching frequencies exceeding 500kHz with 80% reduction in power losses compared to silicon.⁽⁵⁾

Exposure to high performance advanced semiconductors represent one of the strongest expressions of the structural shift to 800V architectures. Mercator sees Wide Bandgap semi-conductor manufacturers as a key sector of interest. The IDM’s (integrated device manufacturers) vertical integration enables tight control of intellectual property, manufacturing quality and supply chain stability.

References:

(1) National Renewable Energy Laboratory. (2025, January 22). Reducing Data Center Peak Cooling Demand and Energy Costs with Underground Thermal Energy Storage. Golden, CO: National Renewable Energy Laboratory. Retrieved from https://www.nrel.gov/news/detail/program/2025/reducing-data-center-peak-cooling-demand-and-energy-costs-with-underground-thermal-energy-storage

(2) NVIDIA. (2025, August 1). NVIDIA 800 VDC Architecture Will Power the Next Generation of AI Factories. NVIDIA Technical Blog. Retrieved from https://developer.nvidia.com/blog/nvidia-800-v-hvdc-architecture-will-power-the-next-generation-of-ai-factories/

(3) eeNews Europe. (2025, May 21). Nvidia consortium pushes 800V power distribution for AI datacentres. eeNews Europe. Retrieved from https://www.eenewseurope.com/en/nvidia-consortium-pushes-800v-power-distribution-for-ai-datacentres/

(4) P3 Group. (2024, December). P3 Charging Index 2024 – Comparison of the fast-charging capability of electric vehicles. Heilbronner Str. 86, 70191 Stuttgart, Germany: P3 Group GmbH. Retrieved from https://www.p3-group.com/wp-content/uploads/2024/12/P3_Charging-Index_EN.pdf

(5) ROHM Co., Ltd. (2022, February). Application benefits of using 4th generation SiC MOSFETs (No. 64AN115E Rev.001). ROHM Co., Ltd. Retrieved from https://fscdn.rohm.com/en/products/databook/applinote/discrete/sic/mosfet/4g_sic_mos_app_benefits_an-e.pdf